Quote:

Originally Posted by Jetboy

FWIW - It's very likely the result of the bushings. Poly bushings are not an upgrade in many cases and are not appropriate for the rear control arms. The rear control arms require more complex motion than a simple hinge joint like the front suspension. The ends need to both hinge around the center bolt but also twist axially as the link rotates and flex out of alignment as them move through the various suspension motions.

The flex out of alignment with the bushing pivot bolt is probably what caused this failure. Because the bushing wouldn't flex enough to accommodate the angles needed, the solid rod was bending at the top of the weld bead. That's where the load would be maximum and there's a stress riser. So most likely that's where you started to get metal fatigue after repeated bends, just like breaking a paperclip. And eventually it failed.

Fortunately it sounds like it wasn't on the highway in an emergency maneuver or something like that.

Looks like you have some replacements. I would put some washers in or you may be able to collapse the brackets enough to tighten up. I would not let them float loose on the collar of the through bolt.

Good luck.

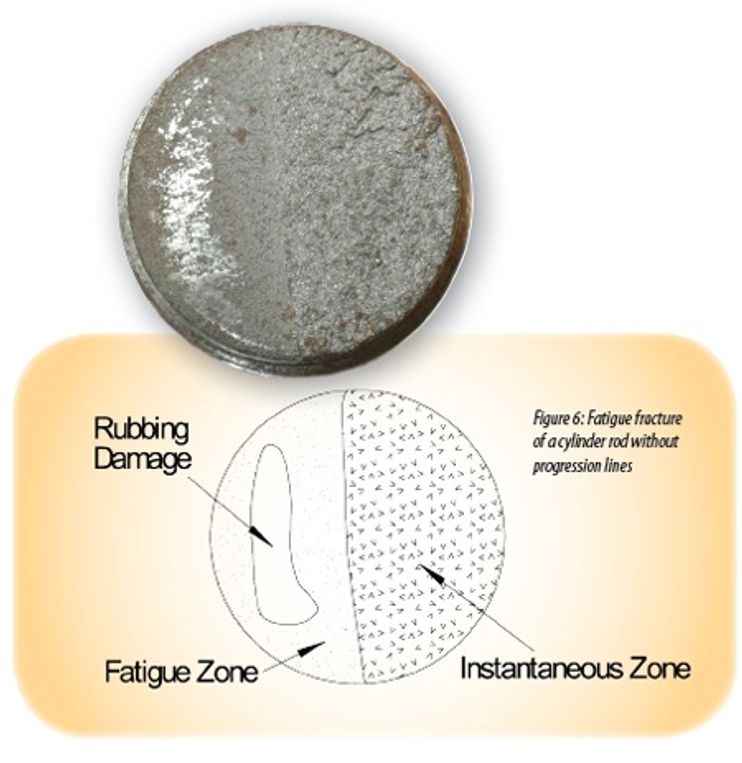

You can see some of the classic metal fatigue in those ends, although it's hard without a bit more resolution than you end up with over the forum. There are pretty clear progression zones and then an area of fracture when it broke completely.

I think an engineer would call this a "high cycle low stress fatigue fracture". But I'm not an engineer. So I call it a paperclip break. The main takeaway is that it wasn't from hitting something hard. It was from lots of small back and forth bending over time where the poly bushing wouldn't flex enough and resulted in the shaft bending back and forth.

If it were a result of an instant impact where it pulled so hard on the end that it ripped apart it would look more like this (ductile fracture):

|

I am an engineer and I once worked with an engineer who diagnosed a situation where bolts on electric transmission line structures were failing in a similar manner. You basically nailed the situation. Thanks for explaining it in clear terms!