05-02-2017, 04:57 PM

05-02-2017, 04:57 PM

|

#1

|

|

Senior Member

|

|

Join Date: Mar 2017

Location: California

Posts: 1,439

Real Name: Matt

|

|

|

Senior Member

Join Date: Mar 2017

Location: California

Posts: 1,439

Real Name: Matt

|

For those who have built your own body armor, I have a few questions

Hello all,

Background:

I've been aching to build some body armor for my rig but I can't really find any information on what should be ideal. My background has nothing to do with metal fabbing, so this will be my first time doing something like this. But I will be asking my friend who does fabbing to help me out, but I figure I'd ask you guys here for some information.

My goals:

Ideally, I'd like to build skid plates, which will be the easiest. Then, rock sliders, then front and rear bumpers with a swing out.

My questions:

Rocksliders:

1. is Square/round tubing a must?

2. is a bolt on good enough?

Front bumper:

1. are the factory mounting points of the crash beam strong enough for a full steel front bumper?

2. What are the important things I need to keep in mind when building a front bumper?

Rear bumper:

1. Is the factory mounting point of the crash beam strong enough for a full steel rear bumper + swing out?

General:

1. Are there any benefits to welding the armor, that bolt on lacks? I am sticking with bolt on mainly for the benefit of being able to revert back to stock.

more questions to come...

Pics of your own fabricated armor would be nice!

Thanks!

|

|

Reply With Quote Reply With Quote

|

05-02-2017, 05:34 PM

05-02-2017, 05:34 PM

|

#2

|

|

Member

|

|

Join Date: Apr 2016

Location: Utah

Posts: 32

|

|

|

Member

Join Date: Apr 2016

Location: Utah

Posts: 32

|

To preface this I have not yet fabricated any of these, however, I plan to and as such have done a lot of research and reading over the past several months on how to best fabricate all of the mentioned armor.

Rocksliders.

1. From what I have seen both square and round are used. Most often square is used for the inner rail and round is used for the outside rail. But square can be used for both. Use a min of 1/8 square tubing.

2. Yes. Just make sure you have enough bolt locations on the frame to distribute the weigh/force.

Front bumper.

1. No. Front bumpers will have a bracket that use those and also bolt directly to the frame just behind the factory mount. There are a couple

2. Keep it as light as possible.

Rear Bumper

1. Yes. The rear cross member is welded on and is not bolted on. There are factory nuts on the bottom of the frame (where you would mount an aftermarket hitch). Most companies use these and the factory nuts on the cross member. Most fabricators will us 1/4 steel to attach to the factory nuts under the frame and use 3/16 for the rest of the bumper fab.

General

1. From what I can tell there are two camps. One weld-on and the other bolt-on. Not sure that one is wrong/right. I prefer bolt on as it is easier to remove later.

A suggestion on the skid plates. You can buy the bolts you need from a fabricator that makes the skid plates. Most sell a pack of replacement bolts for a good price. Also, make sure to weld something around to bolts because if you donít you run the risk of shearing the bolt heads off when sliding over obstacles.

__________________

2003 V6 SR5 4x4 - 3/2 lift w/ Bilstein 5100's & ARB Springs, at3 285/70/17, 1.25" spacers, customer roof rack, customer cargo drawers

1990 V6 4x4 - sold

|

|

Reply With Quote Reply With Quote

|

05-02-2017, 07:16 PM

05-02-2017, 07:16 PM

|

#3

|

|

Senior Member

|

|

Join Date: Sep 2015

Location: Kansas

Age: 28

Posts: 4,303

|

|

|

Senior Member

Join Date: Sep 2015

Location: Kansas

Age: 28

Posts: 4,303

|

The only armor that gets welded on are sliders (Unless they are bolt on which is fine). You don't need to weld bumpers or skids to your frame. My build thread has lots of pictures of my custom armor and rear swingout- enjoy!

Typically front bumpers are skinned with 3/16" steel and the interior winch mount plates and support structures are made from 1/4". Most bumpers constructed like this are roughly 110-135lbs without top hoops.

Bumper weight I don't see as that big of concern, I've played around with my front bumper design in Solidworks. While yes, I can cut 30lbs using a gazillion cutouts and 1/8" steel for the skin, I'm sacrificing a ton of strength. Is 30lbs worth it? Not for me. Everything will probably be 1/4" on mine. Aluminum is 1/3 the weight, but if you simply transfer your design from steel to aluminum, it won't be as strong and it will scuff on rocks way easier. And I don't know how to TIG weld. To make aluminum stronger you need to beef up the plate thickness and add more gussets, which make it closer to the steel weight without the abrasion resistance of steel.

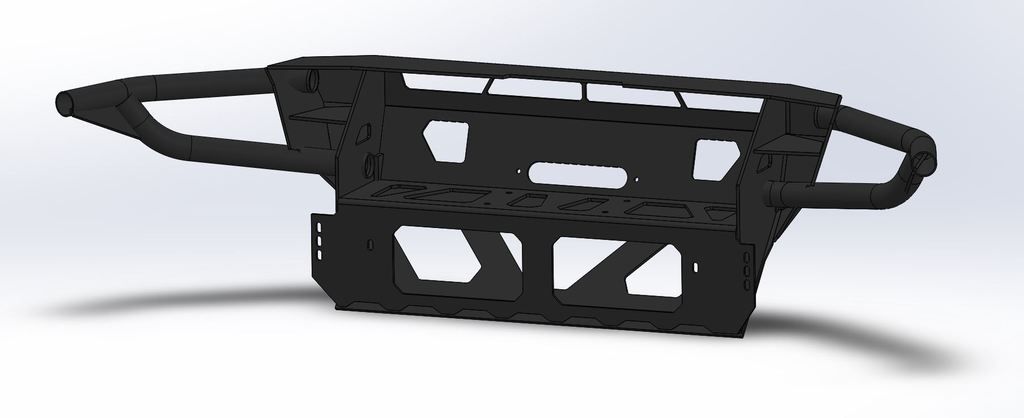

My entire bumper design made from 1/4" steel is only 120lbs unwelded according to Solidworks:

Demello's bumper is completely skeletonized with 1/8" steel skin and I think weighs close to 80lbs:

I've also seen Demello's bumper's 1/8" steel face bend when it hit a rock out wheeling.

You can make a bumper weigh closer to 60lbs making it prerunner style with lots of tubing, an aluminum front plate, and without an option to mount a winch. Depends on your philosophy of use and how good you want it to look after bumping into something.

Other important design considerations with a front bumper:

Fitment, where it lines up with the body and the grille how close do you want it? Keep in mind if you wheel your truck your frame will flex which could cause the body to contact a close bumper. How far do you want the bumper to stick out from the grille? Airflow to radiator or blocked for radiator protection? Light cutouts? Bumper hoops? Body lift adjustability? What size of winch do you want to cram in?

Most if not all aftermarket bumpers, as mentioned by a previous poster, have brackets that bolt it to the side of the frame rails just under where the 8 studs are for mounting the stock bumper cross tube. Check out some bumper install threads using google images and they usually have pics of this.

I believe a previous poster covered the rear bumper well.

__________________

2005 4R Sport 4WD "The last of the V8s!" - Custom TIG'd SS Dual Exhaust - King 2.5" +2 LT. - ARB Front & Rear - 37's - Dana 60 - Build Thread

2005 Tundra 2WD Regular Cab V8 - Chopped Frame - Short Bed Swap

1977 Celica Liftback - LFX Swap - Build Thread

|

|

Reply With Quote Reply With Quote

|

05-03-2017, 03:59 PM

05-03-2017, 03:59 PM

|

#4

|

|

Senior Member

|

|

Join Date: Mar 2017

Location: California

Posts: 1,439

Real Name: Matt

|

|

|

Senior Member

Join Date: Mar 2017

Location: California

Posts: 1,439

Real Name: Matt

|

Thanks for all that information!

Quote:

Originally Posted by campinfreak

Rocksliders.

1. From what I have seen both square and round are used. Most often square is used for the inner rail and round is used for the outside rail. But square can be used for both. Use a min of 1/8 square tubing.

|

So for rock sliders, either square tubing or round tubing is the only way to go then? I was thinking of doing a skid plate for rock sliders to keep costs down to a minimal.

Quote:

|

No. Front bumpers will have a bracket that use those and also bolt directly to the frame just behind the factory mount. There are a couple

|

After seeing some images of other bumpers I see what you mean for the brackets. Hmm...

Quote:

|

Yes. The rear cross member is welded on and is not bolted on. There are factory nuts on the bottom of the frame (where you would mount an aftermarket hitch). Most companies use these and the factory nuts on the cross member. Most fabricators will us 1/4 steel to attach to the factory nuts under the frame and use 3/16 for the rest of the bumper fab.

|

The rear cross member or the rear crash beam? I had the impression that the rear crash beam was a bolt on, so I could just remove it and create a plate with holes in it to align with the stock crash beam mounts.

Quote:

From what I can tell there are two camps. One weld-on and the other bolt-on. Not sure that one is wrong/right. I prefer bolt on as it is easier to remove later.

A suggestion on the skid plates. You can buy the bolts you need from a fabricator that makes the skid plates. Most sell a pack of replacement bolts for a good price. Also, make sure to weld something around to bolts because if you donít you run the risk of shearing the bolt heads off when sliding over obstacles

|

Good to know that there isn't one side that is better than the other. Thanks for the heads up! I'll probably end up doing that

|

|

Reply With Quote Reply With Quote

|

05-03-2017, 04:06 PM

05-03-2017, 04:06 PM

|

#5

|

|

Senior Member

|

|

Join Date: Mar 2017

Location: California

Posts: 1,439

Real Name: Matt

|

|

|

Senior Member

Join Date: Mar 2017

Location: California

Posts: 1,439

Real Name: Matt

|

Quote:

Originally Posted by Inv4drZm

The only armor that gets welded on are sliders (Unless they are bolt on which is fine). You don't need to weld bumpers or skids to your frame. My build thread has lots of pictures of my custom armor and rear swingout- enjoy!

|

Good to know! Is there any reason for choosing bolt on vs weld on for sliders?

Quote:

|

Typically front bumpers are skinned with 3/16" steel and the interior winch mount plates and support structures are made from 1/4". Most bumpers constructed like this are roughly 110-135lbs without top hoops.

|

Kind of glad to hear I wasn't so off. I was expecting to use 1/4" for the main supports/skeleton, with 3/16" wrapping the supports. Weighing somewhere around 150lbs. lighter the better obviously..

Quote:

|

Bumper weight I don't see as that big of concern, I've played around with my front bumper design in Solidworks. While yes, I can cut 30lbs using a gazillion cutouts and 1/8" steel for the skin, I'm sacrificing a ton of strength. Is 30lbs worth it? Not for me. Everything will probably be 1/4" on mine. Aluminum is 1/3 the weight, but if you simply transfer your design from steel to aluminum, it won't be as strong and it will scuff on rocks way easier. And I don't know how to TIG weld. To make aluminum stronger you need to beef up the plate thickness and add more gussets, which make it closer to the steel weight without the abrasion resistance of steel.

|

This is very true. Something I was taking into consideration. But I figure, I doubt I will go wheeling hard like most people so I think the need for such a heavy weight bumper is worthless to me. Where as to some on this forum, it's worth it's weight in gold.

Quote:

|

You can make a bumper weigh closer to 60lbs making it prerunner style with lots of tubing, an aluminum front plate, and without an option to mount a winch. Depends on your philosophy of use and how good you want it to look after bumping into something.

|

That solidworks design you have there looks SWEET! I've been playing around with solidworks for my front bumper too haha. The Demelo bumper was something I was planning to build off of, since I like the look of it.

The prerunner style bumper is nice, but eh.. It looks too ghetto for me.

Quote:

Other important design considerations with a front bumper:

Fitment, where it lines up with the body and the grille how close do you want it? Keep in mind if you wheel your truck your frame will flex which could cause the body to contact a close bumper. How far do you want the bumper to stick out from the grille? Airflow to radiator or blocked for radiator protection? Light cutouts? Bumper hoops? Body lift adjustability? What size of winch do you want to cram in?

|

This is really good information here..

How much flex will there be in the frame? I never thought there would be that much flex to really account for it.

As far as rad goes, what do most people do? Do you know?

Thanks!

|

|

Reply With Quote Reply With Quote

|

05-03-2017, 06:40 PM

05-03-2017, 06:40 PM

|

#6

|

|

Senior Member

|

|

Join Date: Sep 2015

Location: Kansas

Age: 28

Posts: 4,303

|

|

|

Senior Member

Join Date: Sep 2015

Location: Kansas

Age: 28

Posts: 4,303

|

Quote:

Originally Posted by theoutbackdream

Good to know! Is there any reason for choosing bolt on vs weld on for sliders?

|

Bolt-on takes longer to install (I can weld them on pretty fast), but a lot shorter time to take off vs weld-on.  Bolt-on you can take off to touch up the paint if they get scraped on rocks, weld-on you need to mask off with cardboard to touch-up spray paint underneath. Installed properly, they both are of sufficient strength. I welded my sliders 1.5" higher with my body lift which means I have yet to slide them on rocks. So with weld-on you can get the exact fitment you want.

Quote:

Originally Posted by theoutbackdream

This is really good information here..

How much flex will there be in the frame? I never thought there would be that much flex to really account for it.

As far as rad goes, what do most people do? Do you know?

|

You might want close to an inch of space between any parts of the body and the bumper. For the radiator cutouts, just check out pics online of aftermarket bumpers. I might have too much cutout on my current bumper design, but it depends on how much brush you plan on driving through. The Demello bumper only has a few small hole cutouts on the front face, and the small slot in the rear face from my picture. The radiator would probably be mostly unaffected if the front face of the bumper had no cutouts, I'm not sure though.

__________________

2005 4R Sport 4WD "The last of the V8s!" - Custom TIG'd SS Dual Exhaust - King 2.5" +2 LT. - ARB Front & Rear - 37's - Dana 60 - Build Thread

2005 Tundra 2WD Regular Cab V8 - Chopped Frame - Short Bed Swap

1977 Celica Liftback - LFX Swap - Build Thread

|

|

Reply With Quote Reply With Quote

|

05-03-2017, 10:43 PM

05-03-2017, 10:43 PM

|

#7

|

|

Senior Member

|

|

Join Date: Sep 2015

Location: Kansas

Age: 28

Posts: 4,303

|

|

|

Senior Member

Join Date: Sep 2015

Location: Kansas

Age: 28

Posts: 4,303

|

Armor design makes me feel all tingly.

For the skid plates, (usually made from 3/16 steel) try and incorporate 45 or 90 degree bends on the sides, and/or weld angle iron or strips of steel to the topsides. This will make it stronger, but also more difficult to power-wash mud out of the top. By incorporating cutouts in the bend, I can more easily power-wash the tops of mine after I drive it through a mud hole. Also, skid plates should be "shingled" so none of the edges get caught on rocks when driving forward.

You will notice an exhaust crossover pipe that hangs just below your frame. Most aftermarket skids have a small cage that forms around this pipe, which keeps the last skid plate from being smooth potentially grabbing on rock obstacles. I chose to have my crossover pipe moved up slightly which allowed me to flush-mount my last skid to the large frame crossmember, making them smooth underneath and as high-clearance as possible.

The trickiest part to making the skid plates is the rear crossmember for the rearmost skid that gets bolted to the inside of the frame rails and bolted or welded to the backside of the skid plate. This is RCI's crossmember, the black one in this pic on the far left:

Like I said previously, you can see where the skid plates are spaced downwards by Toyota's catalytic converter guards made out of a short piece of tubing, and the low hanging exhaust. Unlike most people, I eliminated those and raised the skid plates the extra 1/2" inch which effectively means I gain the ground clearance of having a set of tires 1 inch taller in diameter.

I bought my front skid plate from RCI because I didn't want to try and get the fitment correct the first time making one. Your plastic fuel tank has a thin metal skid plate, but thicker aftermarket options are available and recommended by me if you do a lot of rock wheeling. I will probably buy mine from RCI for the same reasons I listed for buying the front skid. Complicated design/ tight fitment.

__________________

2005 4R Sport 4WD "The last of the V8s!" - Custom TIG'd SS Dual Exhaust - King 2.5" +2 LT. - ARB Front & Rear - 37's - Dana 60 - Build Thread

2005 Tundra 2WD Regular Cab V8 - Chopped Frame - Short Bed Swap

1977 Celica Liftback - LFX Swap - Build Thread

Last edited by Inv4drZm; 05-04-2017 at 01:03 PM.

|

|

Reply With Quote Reply With Quote

|

05-04-2017, 11:40 AM

05-04-2017, 11:40 AM

|

#8

|

|

Member

|

|

Join Date: Aug 2010

Location: Arizona

Posts: 394

|

|

|

Member

Join Date: Aug 2010

Location: Arizona

Posts: 394

|

Quote:

Originally Posted by theoutbackdream

Hello all,

Background:

I've been aching to build some body armor for my rig but I can't really find any information on what should be ideal. My background has nothing to do with metal fabbing, so this will be my first time doing something like this. But I will be asking my friend who does fabbing to help me out, but I figure I'd ask you guys here for some information.

My goals:

Ideally, I'd like to build skid plates, which will be the easiest. Then, rock sliders, then front and rear bumpers with a swing out.

My questions:

Rocksliders:

1. is Square/round tubing a must?

2. is a bolt on good enough?

Front bumper:

1. are the factory mounting points of the crash beam strong enough for a full steel front bumper?

2. What are the important things I need to keep in mind when building a front bumper?

Rear bumper:

1. Is the factory mounting point of the crash beam strong enough for a full steel rear bumper + swing out?

General:

1. Are there any benefits to welding the armor, that bolt on lacks? I am sticking with bolt on mainly for the benefit of being able to revert back to stock.

more questions to come...

Pics of your own fabricated armor would be nice!

Thanks!

|

I have a ton of pics in my build thread of the front and rear bumpers I made. I am happy with the outcome, although I may make an adjustment to the bumper next autumn. I'm almost done with the rear. It has a dual swing out if you're interested.

The front has a home-made winch plate and I also made my own brackets to mount everything. My winch plate is separate from the bumper, so I can remove the bumper if needed and the winch and plate stay in position.

In case you are wondering, I never built anything in my life before this. I bought a welder and taught myself. It was a learning process, but not that hard. I spent more time taking measurements and designing (on paper) than I did actually fabing. If you want satisfaction, give it a try. You can do it, and there is nothing as rewarding as standing back and admiring something you've built yourself...even if it isn't as pretty as expensive aftermarket stuff! One more thing... the cost of aftermarket pieces, bumpers, sliders, roof racks, etc. are high. I figure I've saved a thousand bucks already by doing my two bumpers. I bought the new welder and drill press for about the same price as a front aftermarket bumper would have cost. The rear bumper only cost me the price of the steel. To top it all off...I have a new welder and drill press in my shop which I will use for a long time!

Going to build a roof rack next, then sliders and skid plates. Good luck in your endeavor.

__________________

You're never lost, because no matter where you go, there you are! 07 Sport V-8, Icon front and rear lift, Icon UCA's, BFG 285/70R17's on American Outlaw rims, homemade front bumper with Rough Country fog lights and 30" embedded light bar. Homemade rear, dual swing arm, bumper. 10 gal. fuel can carrier. Homemade rock sliders and homemade roof rack with 40" light bar. 23Zero rooftop tent, ARB compressor, snorkel, dual AGM batteries . My 2007 4Runner http://www.toyota-4runner.org/4th-ge...ld-thread.html build

|

|

Reply With Quote Reply With Quote

|

05-04-2017, 11:55 AM

05-04-2017, 11:55 AM

|

#9

|

|

Member

|

|

Join Date: Aug 2010

Location: Arizona

Posts: 394

|

|

|

Member

Join Date: Aug 2010

Location: Arizona

Posts: 394

|

Quote:

Originally Posted by theoutbackdream

Hello all,

Background:

I've been aching to build some body armor for my rig but I can't really find any information on what should be ideal. My background has nothing to do with metal fabbing, so this will be my first time doing something like this. But I will be asking my friend who does fabbing to help me out, but I figure I'd ask you guys here for some information.

My goals:

Ideally, I'd like to build skid plates, which will be the easiest. Then, rock sliders, then front and rear bumpers with a swing out.

My questions:

Rocksliders:

1. is Square/round tubing a must?

2. is a bolt on good enough?

Front bumper:

1. are the factory mounting points of the crash beam strong enough for a full steel front bumper?

2. What are the important things I need to keep in mind when building a front bumper?

Rear bumper:

1. Is the factory mounting point of the crash beam strong enough for a full steel rear bumper + swing out?

General:

1. Are there any benefits to welding the armor, that bolt on lacks? I am sticking with bolt on mainly for the benefit of being able to revert back to stock.

more questions to come...

Pics of your own fabricated armor would be nice!

Thanks!

|

To specifically answer some of your questions:

(1) I don't see any benefit between square or round as far as strength. Square is much easier to work with for a beginner. A lot of sliders are bolted on, so it depends on what works for you. I've seen threads detailing each method.

(2) Decide on what you need in a bumper...things like recovery points, winch, lights, bull bars, etc. As far as factory mounts, I took the mounting plates off. I made heavier plates for my rig and utilized the original bolt holes, but I also added extra bolts through the frame rails. That's because the load from my winch will be spread better that just pulling on the original factory mounts. If you're not running a winch, or utilizing recovery points the original mounts are enough to support a simple bumper.

(3) Rear bumper... I cut off the factory hitch and cross member. It is a combination of bolts and welds, and I didn't feel it was strong enough to support my bumper and tire carrier. I used heavy wall tubing for a new cross-member and welded it to the frame. That gave me a solid place to mount my bumper skin and swing arms. I used the bolt holes from the hitch to attach the brackets that support my side pieces. I made an entirely new hitch.

(4) welding on armor? If you're talking skid plates, I would bolt them on. They will eventually get banged up and may need straightened and if they are welded, that becomes a problem I think. I will be making my skids and bolting them on. One other thing... the front skid plate will attach to your front bumper ideally, so consider that when you build the bumper. If you do the skid plate first, you may have to change it later if it doesn't meet your bumper...just a thought.

__________________

You're never lost, because no matter where you go, there you are! 07 Sport V-8, Icon front and rear lift, Icon UCA's, BFG 285/70R17's on American Outlaw rims, homemade front bumper with Rough Country fog lights and 30" embedded light bar. Homemade rear, dual swing arm, bumper. 10 gal. fuel can carrier. Homemade rock sliders and homemade roof rack with 40" light bar. 23Zero rooftop tent, ARB compressor, snorkel, dual AGM batteries . My 2007 4Runner http://www.toyota-4runner.org/4th-ge...ld-thread.html build

Last edited by SunPilot; 05-04-2017 at 11:58 AM.

|

|

Reply With Quote Reply With Quote

|

| Thread Tools |

|

|

| Display Modes |

Rate This Thread |

Linear Mode Linear Mode

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

|